“Happy are those who dream dreams

and are ready to pay the price to make them come true.”

It took us one year to do some research about motorhomes and expedition vehicles. It was not easy to decide and design what we really want and what we are ready to pay for it. At the end we found some compromise between our ideas and reality, so below you will find some brief information and pictures from our truck production. It’s not perfect, but after spending hundreds of hours in the factory, after many dreamless nights, after finding impossible solutions for unpredictable problems, we are very happy with that, what we made, and we hope that we will enjoy some years on the road.

RAM 5500 SLT CUMMINS 6.7 TDI 4X4 GET

- 6.7-Liter I6 Cummins Turbo Diesel Engine 320 hp / 240 kW

- EURO 6 Emissions Standard

- 6-Speed Manual G56 Transmission

- 4×4 Electric Shift-on-the-Fly Transfer Case

- Trailer Break Control

- Dual Alternators 440 A

- Chassis Skid Plates

- Dual Aluminium Heated Floors

- Hydraulic Jacks

- Rear Air Suspension Firestone

- Air Compressor Viar with Tank

- Sandwich Panel Construction (aluminium / fibreglass) 45 mm

- KCT Windows with Armour Plates

- 7 Leather Seats with Seatbelts

- Dual Diesel Tank 280 l

- LPG Tank 70 l

- DEF Tank 34 l

- Fresh Water Tank 350 l

- Stainless Steel Water Heater Tank 50 l

- Grey Water Tank 150 l

- Front Bumper with WARN 16.5 Winch

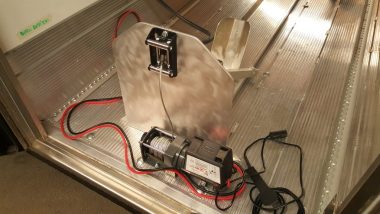

- Rear Winch WARN 2000 DC

- Double Welded Sand Ladders

- LED bars 783 W / 90 W / 72 W

- Underglow Neon Lights

- Water Pump with Expansion Tank

- External Water Pump Sigmona

- Eberspächer Heating D2 and D4

- MaxxFan Remote Control Fans

- Two Truma Aventa Comfort Air-conditioners

- Hybrid Generator W-GV 3, 7000 W

- Electrical System 12 V / 24 V / 110 V / 230 V

- AGM Power Batteries 780 Ah

- Monocrystalline Solar Panels 24V, 2x 285 WP

- Roof Top Tent Maggiolina Airlander Plus

- Awning Dometic PW3500

- Scooter Honda PCX 125

- Bathroom with Dometic Toilet CTS 4110

- Kitchen with Whirlpool ACM 712 Induction Cooktop

- Whirlpool JW 280 Microwave (Grill / Steam / Forced Air)

- Compressor Fridge CoolMatic HDC-275

- Compressor Ice Maker Klarstein

- Gas Grill Cadac & Solar Grill GoSun

- Entertainment System Sony Hi-Res STR-DN1070

- Outdoor Speakers ART Sound

- BD / DVD Player Yamaha with Subwoofer Yamaha

- 32″ Samsung and 40″ Samsung TV’s

- CB, SW, FM, DVB T/T2, UKW, DAB+. GPS, Wi-Fi, 4G, LTE Antennas

- Camera Monitored Satellite and GSM Security Alarm

CHASSIS – RAM 5500

We were searching for heavy duty chassis, not really truck, but strong enough for our project. We also did not want gasoline engine and automatic transmission. So the only chassis, which met our criteria, was RAM 5500. We mounted solid front bumper from Tough Country guys with strong WARN 16,5 winch. Well done! (November 2016)

CHASSIS & FIRST FLOOR

We started alternations of the cabin and preparations of the first floor and steel frame for the garage at the back. (March / April 2017)

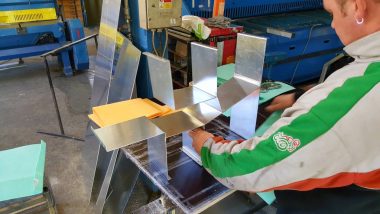

FRAMES

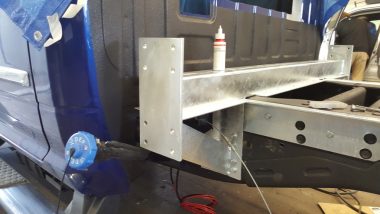

Preparations of frames for garage floor, hydraulic jacks, boxes on chassis generator and electrical system, steel structure for the AGM batteries and mount of the rear air suspension, LPG tank and generator cooling radiator. (March / April 2017)

FINISHING OF FRAMES & AIR SUSPENSION

Steel frame for the hydraulic jacks got mounted on chassis. Final mount of the rear air suspension has finished. We were also mounting all the fuel pipes and electric cables for the generator and we started production of doors for boxes and garage. (May 2017)

HEATING, CABIN, PANELS

We started mounting of two units of the Eberspächer heating and preparations for heating exhaust. We mounted the stainless-steel frame between cabin and camper and finally also panels from Germany has arrived, so we started making holes for windows and doors. We tested the steel frame for the rear AGM batteries. (May 2017)

EXHAUST, HEATERS, HYDRAULICS

We were busy with heating and generator fuel pipes and exhaust. We started mounting the hydraulic system and extra heater connected to generator cooling system, that we can warm the first floor during use of generator. Production and testing of frames for the boxes has continued. (May 2017)

WALLS

We mounted first walls – 45 mm sandwich of fibreglass, aluminium, insulation and special plywood for reinforcement. We also finished mount of the air suctions and exhaust for both heaters. (May / June 2017)

WALLS & ROOF & TECHNOLOGIES

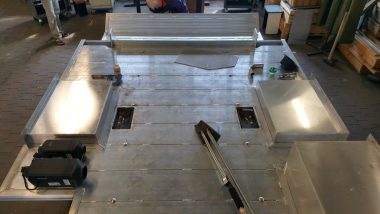

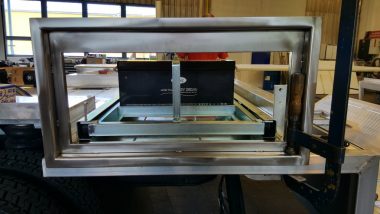

We continued with walls, we mounted rear batteries on the frame and started production of the entrance stairs. We also tried if generator and main batteries chargers and power inverter will fit inside the boxes. (June 2017)

SEATS & TECHNOLOGIES

All walls were done, except the rear wall. Finally also leather seats arrived from Turkey. We tried to find the best comfortable gap between the seats before producing the bottom frame. Also tank for fresh water and grey water were mounted. We were still busy with frames and doors for the boxes. Electricians have started putting main electrical lines. (June 2017)

TECHNOLOGIES & WALLS

We were working quite some time on all the technologies mounted on the first floor, also production of the frames and doors for boxes has been done. (June 2017)

SECOND FLOOR & BATHROOM

We mounted frame for the second aluminium floor, frame for Alubond ceiling panels was mounted on the roof. Electricians continued with cables and connections. Preparations for the bathroom have started with water and drainage pipes. It was also not easy to find some solution how to make final design of the cover of the gap between cabin and camper. (June 2017)

REAR WALL & BATHROOM

We continued with electric and technologies connections. Frame for bathroom floor was done. Hydraulic jacks were mounted and connections between cabin and camper started. Stainless steel frame in cargo compartment was finished. (July 2017)

BATHROOM & PAINT

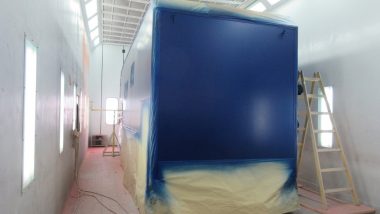

Bathroom walls were built-in and rear two sleeping places has been finished. Inner frames for windows were done. Electrical wiring continued and both air-condition units were tested. Also water heater, shower corner and toilet were installed. Truck has moved to another hall for painting preparations and first blue streak pearl coat. Then we found out, that paint supplier made little mistake in the paint code, so the paint did not match with cabin paint (especially on sun light), so second final paint was done. (August 2017)

BATHROOM FINISHING

After the paint we continued with installations inside the bathroom and electrical wiring. Also production of the upper safety frame has started. (August 2017)

REAR FRAME & SCOOTER RAMP

Installation of the scooter ramp has started in the garage – it was hard to find some smart solution. Rear frame and part of frame on the roof were installed including Dometic awning. Electrical wiring has continued in the rear sleeping compartments. (September 2017)

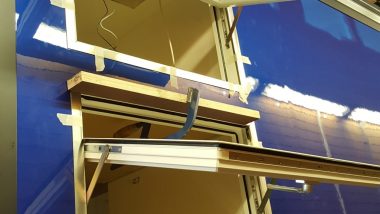

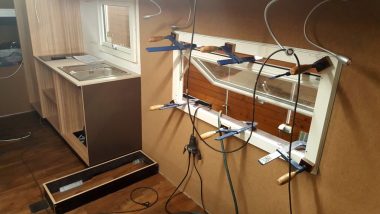

BLACK COAT & STEEL FRAME

We found out, that we cannot get out from the hall with frame on the roof. So we moved truck to another hall, where also final black coat of lower truck part was done. Steel frame was installed and installation of the overpriced KCT windows has started. (September 2017)

STEEL FRAME AND WINDOWS

We continued with windows and fans installations. Upper frame got final black coat. Outside position lights were installed and heavy wiring continued inside the truck. Stainless steel finish between cabin and camper was done. (September 2017)

ROOF FINISHINGS

Both air-conditioners, both solar panels, outside speakers and some antennas got installed. Electrical wiring still continued inside the truck and stainless steel frames around windows were installed. Both service panels outside the truck were finished and we tried also seats inside the truck. (September 2017)

FURNITURE

We started installation of furniture, it was faster than we expected. But anyway the heavy wiring inside the truck has still continued. (September / October 2017)

WIRING AND FINISHINGS

We spent hours and hours with finalizing of small details while wiring was still continuing – job without end. (October 2017)

ELECTRICAL WIRING

Photogallery – no comment. God Bless our Electricians. (October 2017)

FINISHINGS I.

Rear winch got installed. We started the table preparations and wiring in the cabin got finalized. (October 2017)

INTERIOR FINALIZATION

Wiring still continued, while rest of furniture was installed. We also did first test ride and skid plates installation has started. Project is nearly done, so we have decided for some holidays to refresh our minds to be able to finalize the truck after Xmas. (November 2017)

END OF THE MAIN CONSTRUCTION

After nearly 2 years of dreamless nights main constructions of the expedition truck came to its end. We loaded our equipment, finished few things inside the truck, installed the sand ladders and started preparations of our first tour around Balkan. Once we will have some free time, we will do some good shots of the final interior design. (March 2018)